Hazwoper Regulation : What it is

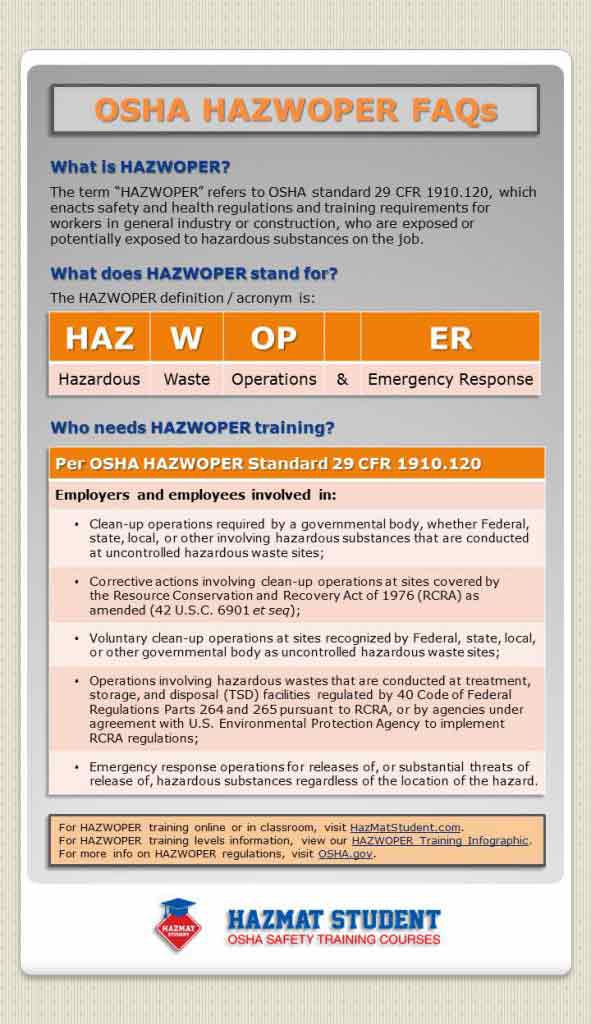

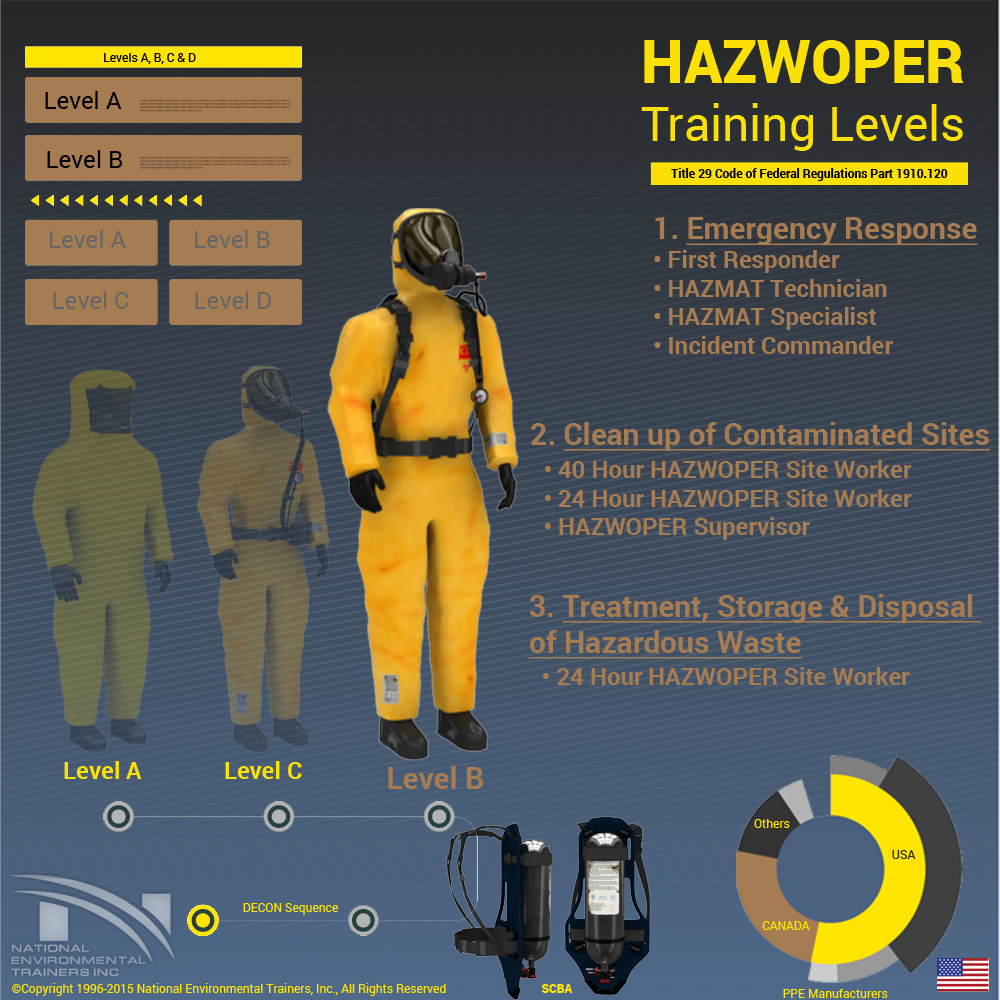

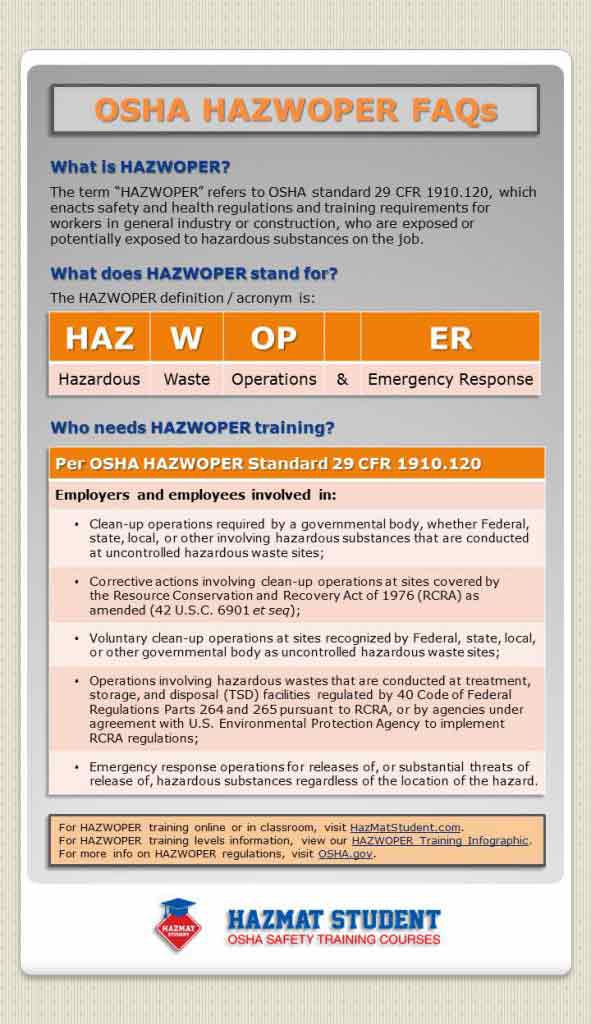

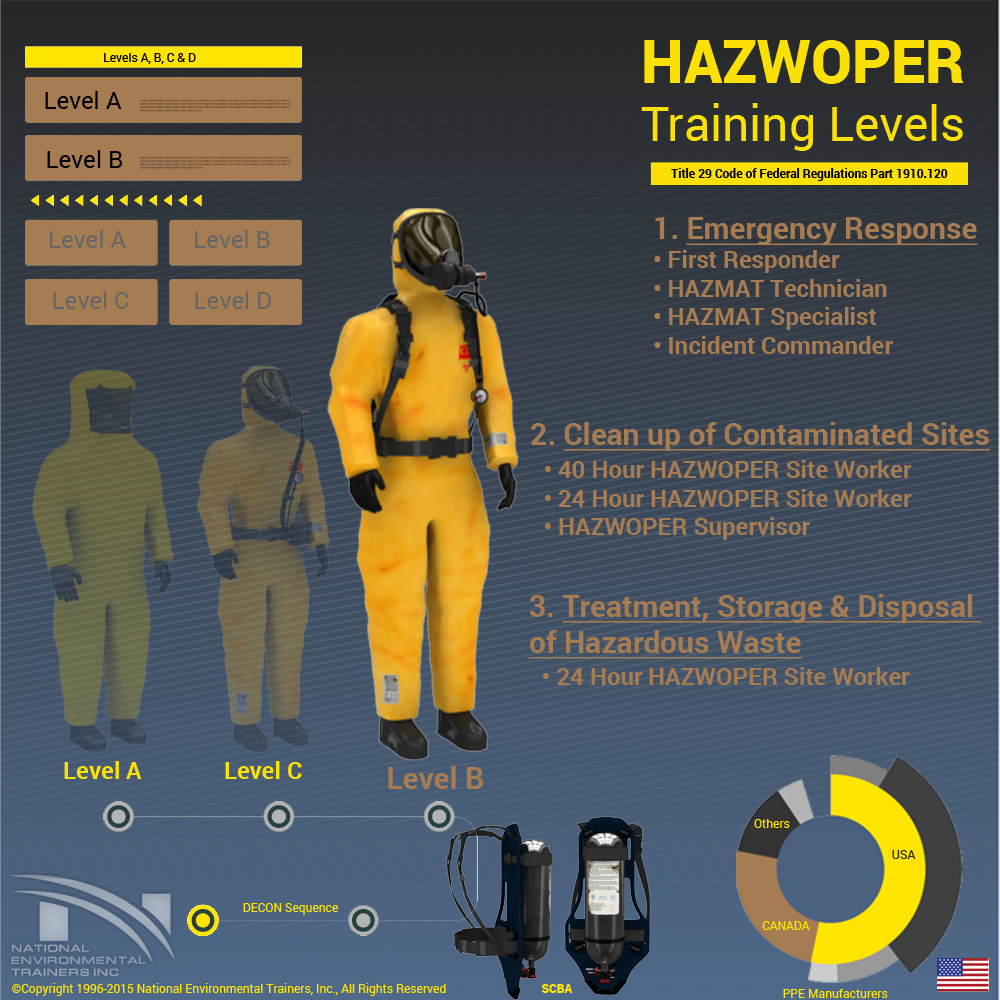

Hazwoper Regulation: What it is Introduction: Welcome to our comprehensive guide on HAZWOPER (Hazardous Waste Operations and Emergency Response) Regulation. In this article, we will delve into the details of this important regulation, highlighting its significance and how it impacts various industries. Whether you are an employer, employee, or someone who wishes to learn more about HAZWOPER, this post will provide you with all the essential information you need to know. 1. Understanding HAZWOPER: What it Means and Why it Matters The HAZWOPER Regulation is a set of guidelines established by the Occupational Safety and Health Administration (OSHA) to ensure the safety and well-being of workers involved in hazardous waste operations and emergency response. By implementing the HAZWOPER Standard, employers are accountable for protecting their employees from potential hazards associated with these operations. 1.1 The Purpose of HAZWOPER Regulation The main goal of the HAZWOPER Regulation is to reduce risk and prevent occupational injuries and illnesses arising from hazardous waste operations. It establishes specific training requirements, safety protocols, and emergency response procedures to be followed by employers and employees working in environments where hazardous substances are present. 1.2 Applicability of HAZWOPER The HAZWOPER Regulation applies to several industries, including but not limited to: 1. Construction and Demolition 2. Manufacturing 3. Oil and Gas 4. Healthcare Facilities 5. Environmental Cleanup 6. Hazardous Materials Transportation 2. HAZWOPER Training Levels & Requirements To ensure compliance with HAZWOPER Regulation, various training levels and requirements have been set by OSHA. Each level corresponds to a specific job function and determines the extent of training necessary for individuals performing those tasks. 2.1 HAZWOPER Training Levels a) First Responder Operations Level b) First Responder Awareness Level c) HAZWOPER Technician Level d) HAZWOPER Specialist Level e) On-Scene Incident Commander 2.2 Training Requirements for Each Level a) First Responder Operations Level: The First Responder Operations Level involves employees responding to hazardous substance releases. Training for this level includes topics such as recognizing hazards, implementing containment measures, and basic decontamination procedures. b) First Responder Awareness Level: Employees at the First Responder Awareness Level are trained to recognize the presence of hazardous materials and understand the potential risks associated with them. This training ensures they take appropriate action and notify the necessary personnel in case of an emergency. c) HAZWOPER Technician Level: HAZWOPER Technicians undergo extensive training and are equipped with the necessary knowledge to respond to hazardous substance releases. They are trained in advanced techniques for containment, cleanup, and mitigation of hazardous materials incidents. d) HAZWOPER Specialist Level: The HAZWOPER Specialist Level includes individuals with expertise in specific areas, such as chemical analysis, air monitoring, or site control. They possess a more advanced level of training and are responsible for supervising and providing guidance during emergency response operations. e) On-Scene Incident Commander: The On-Scene Incident Commander oversees and directs response efforts during hazardous substance incidents. They are responsible for making crucial decisions, coordinating operations, and ensuring the safety of all personnel involved. 3. HAZWOPER Best Practices: Ensuring Safety and Compliance Along with mandatory training, there are several best practices employers and employees should adhere to when dealing with hazardous waste operations. These practices enhance safety, minimize risk, and ensure full compliance with the HAZWOPER Regulation: 3.1 Personal Protective Equipment (PPE): Wearing appropriate personal protective equipment, such as gloves, goggles, and respirators, is crucial when dealing with hazardous substances. PPE provides a barrier between the worker and potentially harmful materials, reducing the risk of exposure and associated health hazards. 3.2 Site Analysis and Evaluation: Prior to commencing any operations involving hazardous substances, a thorough site analysis and evaluation should be conducted. This ensures that potential risks are identified, appropriate mitigating measures are implemented, and necessary resources are allocated. 3.3 Emergency Response Plan: Having a well-developed emergency response plan is vital to effectively deal with hazardous substance incidents. This plan should include evacuation procedures, communication protocols, contact information for emergency services, and a clear chain of command. FAQs: Q1: How often is HAZWOPER training required? A1: HAZWOPER training is required initially upon employment and must be refreshed annually. Refresher courses keep employees updated on changes in regulations, improve their knowledge, and reinforce safe practices. Q2: Are there any exemptions to the HAZWOPER Regulation? A2: Certain exemptions exist for employees whose exposure to hazardous substances is limited and does not require the full HAZWOPER training. These exemptions are outlined in the regulation and depend on factors such as duration of exposure and the extent of potential hazards. Q3: Is the HAZWOPER Regulation enforceable by law? A3: Yes, the HAZWOPER Regulation is enforceable by law. Failure to comply with its requirements may result in penalties, fines, or legal action. OSHA conducts inspections and audits to ensure employers are fully compliant with the regulation. Conclusion: Now that you have a solid understanding of the HAZWOPER Regulation, its training levels, requirements, and best practices, you can confidently navigate hazardous waste operations and emergency response situations. Remember to prioritize safety, ensure compliance, and empower yourself and your team with the knowledge and training needed to mitigate risks effectively. Stay safe and protect the environment while working in hazardous conditions!  Image Source : hazwoper-osha.com

Image Source : hazwoper-osha.com  Image Source : www.moxietraining.com

Image Source : www.moxietraining.com  Image Source : hazmatsociety.org

Image Source : hazmatsociety.org  Image Source : www.hazmatstudent.com

Image Source : www.hazmatstudent.com  Image Source : hazwoper-osha.com

Image Source : hazwoper-osha.com .jpg) Image Source : weeklysafety.com

Image Source : weeklysafety.com  Image Source : salvationsafety.com

Image Source : salvationsafety.com  Image Source : www.natlenvtrainers.com

Image Source : www.natlenvtrainers.com

What Is 40 Hour HAZWOPER Training & Why It’s Important?

Image Source : hazwoper-osha.com

Image Source : hazwoper-osha.com hazwoper training osha hour important why

'HAZWOPER: Personal Protective Equipment' Computer Or Web Based Program

mas cbt hazwoper protective personal equipment

Online OSHA 24-Hour HAZWOPER Training Course – Hazardous Materials Society

Image Source : hazmatsociety.org

Image Source : hazmatsociety.org hazwoper osha

OSHA HAZWOPER Infographics | HAZWOPER Training HazmatStudent

Image Source : www.hazmatstudent.com

Image Source : www.hazmatstudent.com hazwoper definition training infographic acronym osha

Our Safety Blogs

Image Source : hazwoper-osha.com

Image Source : hazwoper-osha.com HAZWOPER Heat Stress | HazMat

.jpg) Image Source : weeklysafety.com

Image Source : weeklysafety.com HAZWOPER Regulation In The Power Generation Industry - Salvation Safety

Image Source : salvationsafety.com

Image Source : salvationsafety.com HAZWOPER Training Levels & Requirements | HAZWOPER Certification

Image Source : www.natlenvtrainers.com

Image Source : www.natlenvtrainers.com hazwoper levels training requirements certification infographic

Hazwoper osha. Hazwoper training osha hour important why. Mas cbt hazwoper protective personal equipment. Hazwoper regulation in the power generation industry. Our safety blogs